Research, Development and Innovation

The primary focus of our Research, Development, and Innovation division during the reporting period was on two key fields of work: optimizing existing core processes and developing new processes for complex materials – in line with the new multimetal strategy.

We see the Research, Development, and Innovation division as crucial to maintaining our competitive edge. We strenghthened the division further and had 78 employees in fiscal year 2017/18 (previous year: 67 employees). The employees are distributed across the Group, and work at the sites in Buffalo, Hamburg, Lünen, Olen, Pirdop, Pori, Stolberg, Finspång, and Zutphen. We promote intensive communication between the sites.

The strategic project Future Complex Metallurgy (FCM) was a focus of our work again in fiscal year 2017/18. Here, we are developing a flexible process and an industrial plant that will enable the quick recovery, with a high level of selectivity, of metals from complex raw materials and intermediates. Our development work here has involved numerous trials at our R&D pilot facilities, through which we seek to validate and develop the metallurgical process for the project, and to continuously optimize the ramp-up phase of the new facilities. Tests are also planned for the coming fiscal year as well, which should identify the most important process parameters in order to deliver a stable process. The FCM project has given rise to numerous subsequent projects related to downstream processes. Among these is a project aimed at assessing the capacities and recovery times of current facilities.

We are increasingly using sensor technology as part of our efforts to advance the existing key processes in primary and secondary copper production. Together with the mineralogical characterization of the input material, we are thus improving the stability and monitoring of the key processes with the objective of boosting metal output. With a view to advancing these activities, which fall under the topic of digitalization, we expanded our specialist team in 2017/18. Our goal is to drive complex operating processes with advanced analytics methods. Only with a sufficiently large data basis can we sustainably implement improvements. An example of this is the data-driven energy consumption forecast at the Hamburg site, which will enable us to react more flexibly to fluctuating energy prices in the future.

In the area of mathematical modeling, we have completed prototypes to support operative production planning with the objective of strengthening our competitive edge, and we are currently in the process of implementing them. We have also developed additional models to support production. For instance, we are planning to improve our energy management with such models and are working together with external institutes to develop a practicable, stable, efficient, and flexible energy system.

Fiscal year 2017/18 saw us continue our work on improving metal recovery from iron silicate slag. In this context, we are researching a new metallurgy process that enables the selective extraction of metals contained in the slag. This improved metal extraction capacity will also boost the competitiveness of our primary copper production activities.

Within Segment Flat Rolled Products, we worked on developing and marketing lead-free machining materials during the fiscal year. When it comes to wire products, we are in the process of developing different alloy varieties for the BlueBrass family.

In the connector product sector, we worked on sampling low-alloyed, highly conductive copper alloys.

We were also involved with basic research in the areas of battery technology and power electronics in fiscal year 2017/18. In some cases, this took place within the scope of publicly funded projects implemented together with university and industry partners. We successfully achieved the first development results in the business area of power electronics in the form of patent applications.

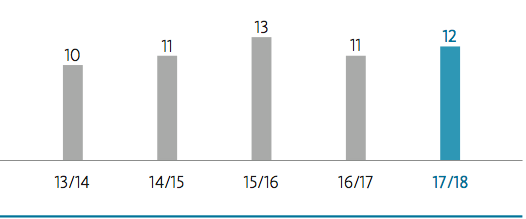

The entire Aurubis Group’s R&D expenditures in fiscal year 2017/18 amounted to € 12 million, compared to € 11 million in reporting year 2016/17.

R&D expenditure

in € million